Exceed their expectations using Countervail

Automotive lightweighting is an industry-wide challenge, and that challenge increases when noise, vibration, and harshness (NVH) goals are considered.

Excessive vibrations can

Our solution is Countervail - a true composite materials product line that can address NVH requirements at minimal weight and has been engineered to require no changes in tooling and manufacturing procedures for implementation.

Lightweight, stiff structures can exhibit complex frequency-dependent motions that produce noise under dynamic load inputs. Countervail was developed to reduce dynamic mobility at minimum weight added.

There are numerous structure-borne noise sources that must be treated to ensure passenger comfort.

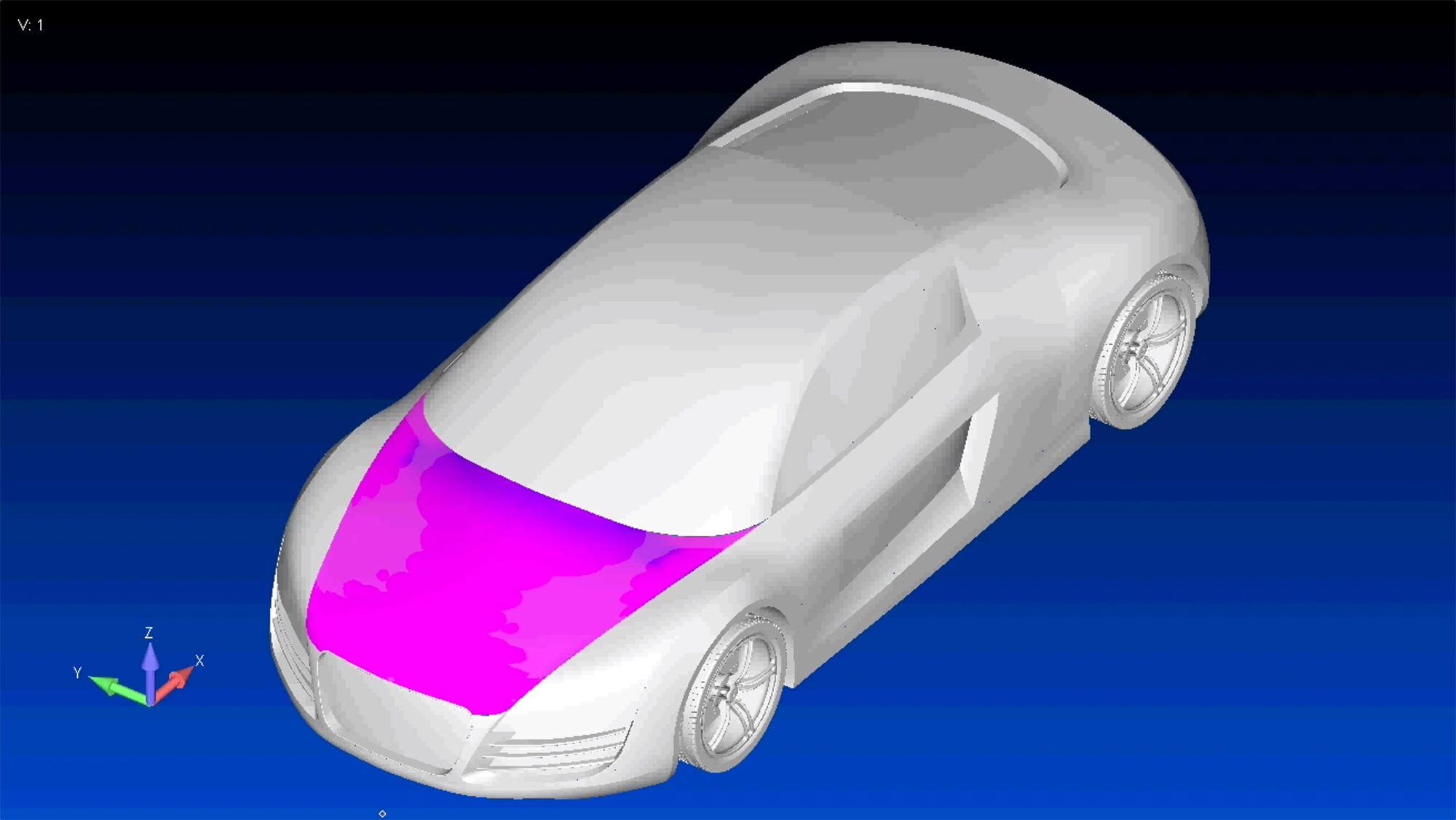

Through strategic material placement, Countervail can deliver damping values needed to treat offending vibration modes.

Lower dynamic mobility means a more traditional-sounding vehicle while meeting weight reduction goals.

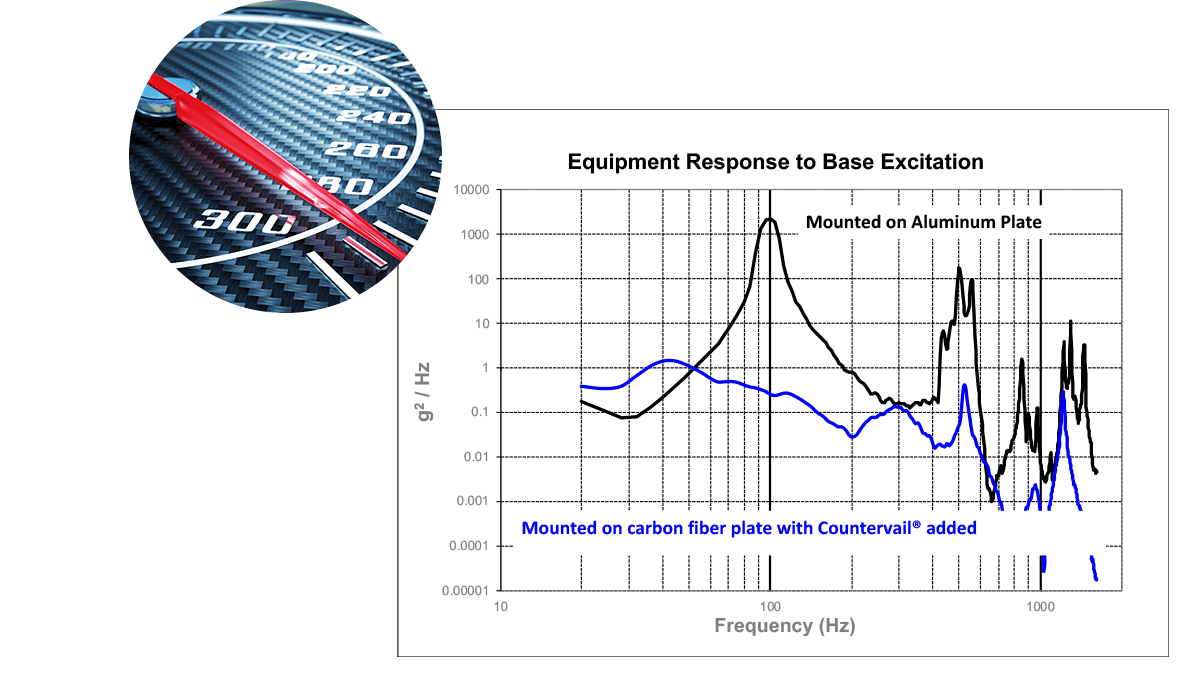

Need to manage dynamic load inputs into sensitive equipment mounted to lightweight panels?

Add Countervail and reduce road-induced vibration motions to increase mean time between failures.

With our proven six-step process, it’s never been easier to integrate Countervail technology into your product.

Learn More About How We WorkHave questions or ready to get started? Fill out your details below and a Countervail engineer will reach out to discuss your project.

© 2026 Countervail® Products LLC. Privacy Policy.