Quiver, quake, tremble, oscillation, shake. Regardless of the terms you use to describe it, vibration is just a form of energy. It’s created by any force that causes the particles of an elastic body or medium to move in a back and forth motion until returning to its natural, resting state.

For musical instruments, vibration is a necessity. It’s what starts sound waves moving through the air. But in the manufacturing world, whether producing tennis rackets, automobiles or any number of other products, vibration can be detrimental to products’ performance and safety. That’s why some form of vibration control is essential.

Understanding Vibration Isolation and Vibration Damping

Two of the most common ways of controlling vibration is vibration isolation and vibration damping. While the terms are often used interchangeably, they’re two very different processes.

Vibration isolation prevents vibration transmission. It keeps vibration energy from entering an object, such as a structure or piece of equipment.

Vibration damping dissipates vibration energy. It absorbs or changes vibration energy, reducing the amount of energy transmitted through the equipment or structure. Understanding these processes — and when to use them — also requires understanding two concepts: transmissibility and natural frequency.

Transmissibility is the ratio of the vibrational force being measured in a system to the vibrational force entering a system. For example, if a material used for vibration isolation has a transmissibility of 75%, that means 75% of the vibrating force energy is being transmitted (or 25% transmission loss) through the materials and measured on the other side.

Natural frequency is the frequency (number of cyclic motions per unit time) at which an object or structure vibrates naturally or resonates. A structure vibrating at natural frequency will vibrate forever unless an outside force interferes with it. Thankfully, in nature, there’s always some force affecting a vibrating object, removing energy and eventually dissipating the vibration; these forces collectively are commonly referred to as vibration damping.

So how do all these concepts and definitions help determine if vibration damping or isolation is the way to go in controlling vibrations in various products? The first step is to identify the offending source and frequencies of concern, which in many cases arise from features outside of a product designer’s control. If the object or structure is simple enough, it may be possible to use isolation to shift a single critical natural frequency away from the excitation source frequency. However, for most practical product applications there are typically so many natural frequencies and dynamic loads that they all can’t be shifted; energy dissipation via damping is the only way control the dynamic response and reduce transmissibility.

Vibration Control Process for Practical Applications

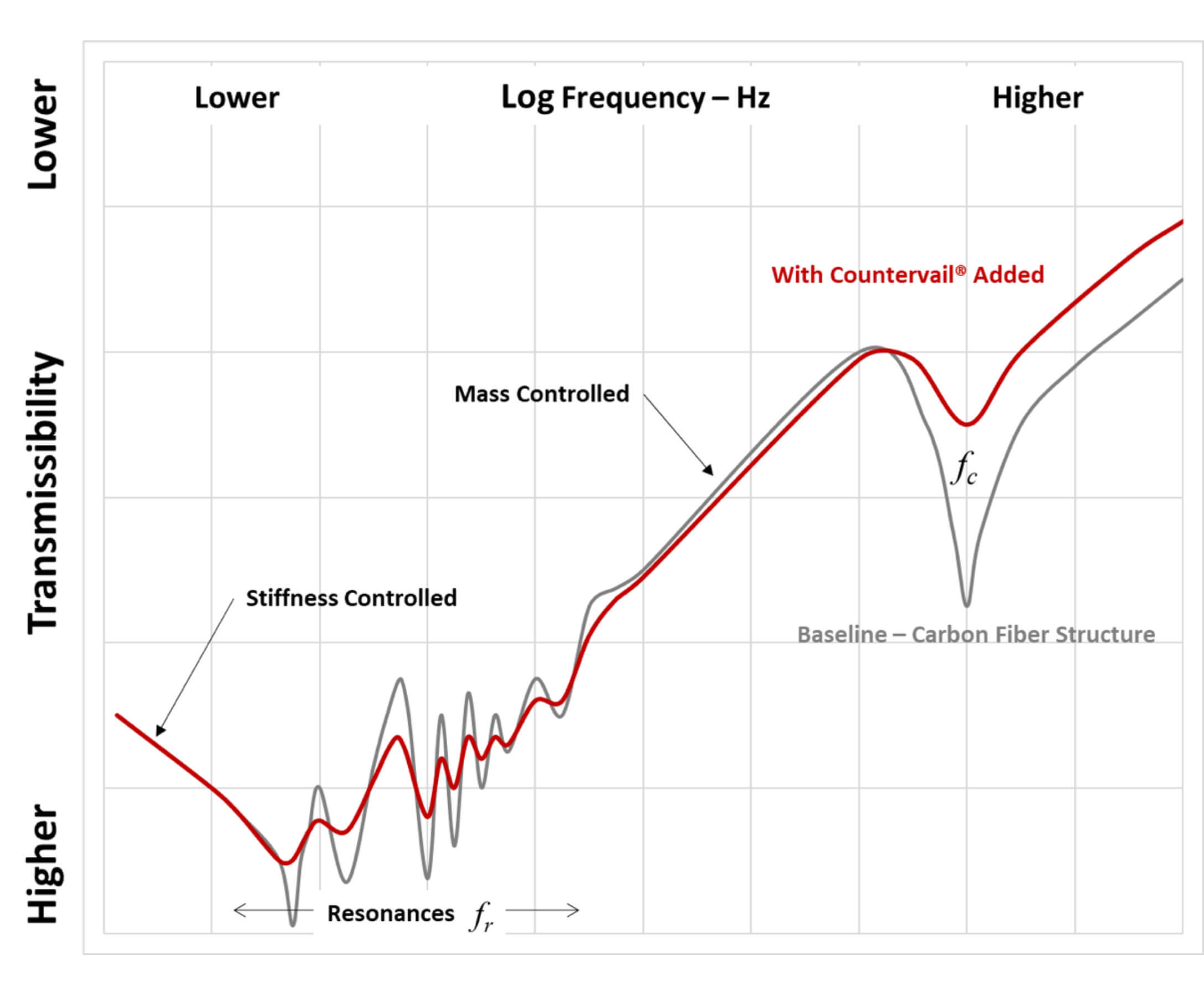

With the above as background, it becomes clear that vibration control comes down to managing the response near (multiple) resonances fr, and, as shown schematically in Figure 1, near what is called the coincidence frequency or fc for some applications with complicated excitation sources. This energy management can be accomplished using geometric design variables such as isolation or shaping to change transmission paths or by introducing materials to dissipate energy. However, if we assume that for most practical applications the structure, object or equipment’s shape are defined by basic functionality then materials like Countervail® that deliver high levels of damping must be used to control vibrations.

Figure 1. Key Elements of Sound Transmission Physics for a Flat Panel.

Of course, the details of both your production process and the product being produced may involve variables that require further analyses. Speaking with an engineering consultant who understands vibration control is recommended.